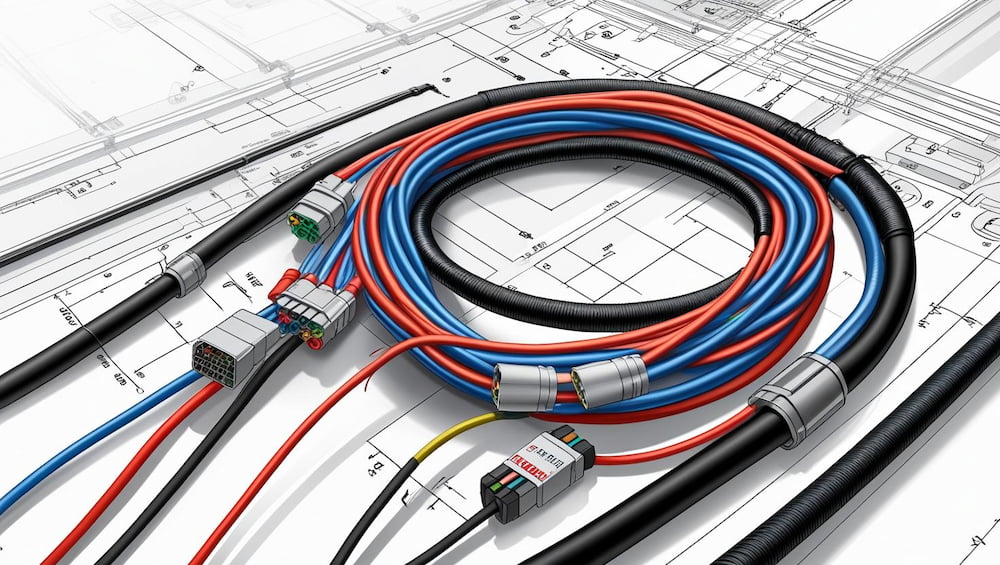

Wire harness design is a foundational aspect of modern electrical systems, used in industries ranging from automotive and industrial machinery to consumer electronics. A well-designed wire harness ensures not only safe and reliable power or signal transmission but also improves installation efficiency and long-term maintenance. Understanding the core principles of wire harness design is essential for engineers, manufacturers, and buyers looking for durable and tailored solutions such as custom wiring harnesses.

1. Understand the Application Requirements

The design process begins with a clear understanding of the application environment. Factors such as temperature, moisture, vibration, and exposure to chemicals directly influence material selection and protection methods. For example, a custom wire harness used in heavy machinery may require high-temperature insulation, UV-resistant jackets, or additional sealing to perform reliably in harsh environments. Defining these requirements early helps avoid design flaws and product failure.

2. Prioritize Layout and Organization

An effective wire harness design focuses on efficient routing and bundling of cables. This minimizes clutter, reduces installation time, and makes future repairs easier. Clear labeling, color-coding, and secure fastening with clips or ties are all standard practices. When developing a custom wiring harness solution, designers often tailor the layout to fit tight spaces or complex mechanical structures, ensuring smooth integration with the end product.

3. Electrical Compatibility and Safety

Selecting the proper wire gauge based on current load, voltage, and resistance is essential to prevent overheating and electrical loss. In high-signal or sensitive environments, shielding and grounding are critical to reduce electromagnetic interference (EMI). Additionally, using quality connectors and ensuring secure terminations helps avoid loose connections or short circuits. Safety standards such as UL or IPC/WHMA-A-620 are often mandatory in custom cable harness production to meet regulatory and client-specific needs.

4. Testing and Quality Assurance

Every wire harness must undergo functional and continuity testing before delivery. This step ensures that each connection performs correctly and that the harness meets design specifications. For custom wiring harness assemblies, comprehensive documentation—such as wiring diagrams, material lists, and assembly instructions—helps maintain consistency and simplifies communication between engineers and production teams.

A successful wire harness design combines practical layout, environmental durability, electrical performance, and safety compliance. Choosing or manufacturing a custom wiring harness means considering these principles to ensure that the final product fits perfectly into the intended system and operates reliably under real-world conditions. Whether for automotive, industrial, or specialized equipment, quality wire harness design is essential for long-term performance and user satisfaction.